Education

SOLGW Armorer’s Course Review

after action report provided by paul shaffer of half breed designs

Social media. “Disinformation”. A gathering of the infamous village idiots with a loudspeaker. To the uneducated it’s hard to filter out the quality information from the copious amounts of regurgitated inaccurate advice in the forums and groups that revolve around the AR-15. A little over 5 years ago I heard of Sons of Liberty Gun Works in online gatherings. The subject matter expert’s feedback was they were a small boutique shop that put out some quality hard use rifles and they were starting to sell their products individually. Shortly there after I see this interaction:

It got my attention. It was clear the customer shouldn’t expect anything whiz-bang compared to the other brand except lifetime support. I was intrigued and purchased a BCG from SOLGW. In big letters on the box, it stated “Lifetime Guarantee”. The product met the standards of the TDP spec, it was slathered in oil, sealed in a bag, and had brass markings from it being test fired. I wondered how a company could put this in writing when no other company that I knew of, did.

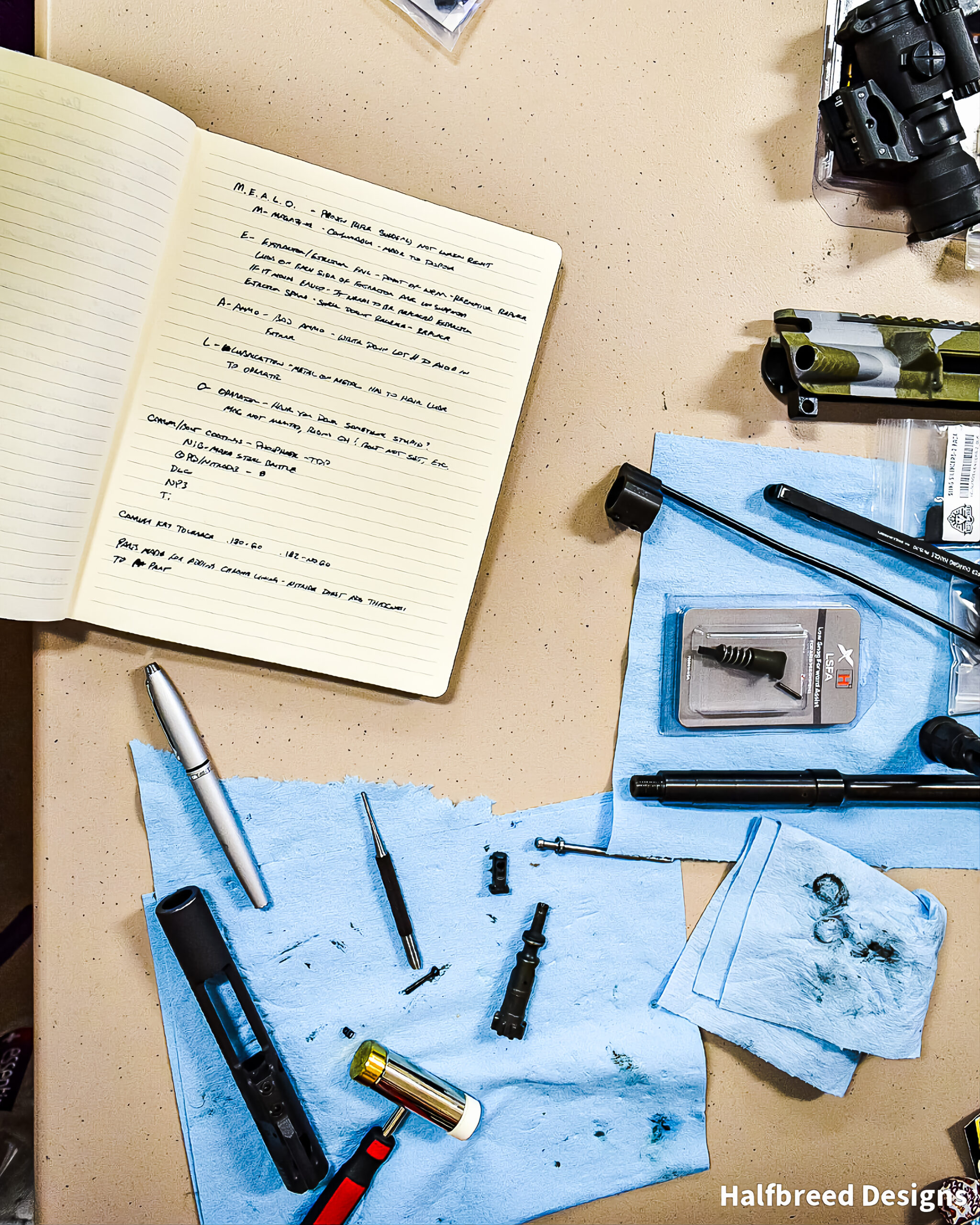

Fast forward 4ish years and I was bringing boxes of individual components into a building at the property of BTO Range for an Armorer’s course with SOLGW. It was the morning of day 1 and I had my learning hat on. The room was full, best estimate of 30-35 individuals, of whom I knew very few of. Various professional backgrounds that included current gunsmiths, LEO, gun shop employees, rifle enthusiasts, reps for firearm industry brands, even an owner of a machining company that makes high-end gun components. Then there was me, a banker by day, photographer/AR-15 armorer by night. I came in with high expectations to advance my knowledge of the AR-15 rifle platform. I felt I had a solid grasp of the working platform, never hesitant to diagnose a rifle malfunction, but I didn’t have the vernacular to communicate that diagnosis in a way for others to understand that didn’t have that same level of knowledge. I also wanted to learn the “why” behind several of the designs and variations across different brands. Oh, and I wanted to build yet another rifle.

After an around the room introduction of the attendees, Mike Mihalski started the education in what is known as typical Mike fashion by addressing the #1 priority, “The Fucking Thing Must Work.” That is when the notes started scribbling. 16 or so classroom hours later the scribbling stopped, a rifle was assembled from individual components, my brain was throbbing from the information intake, laughs were had, friendships were made, and I walked away being able to communicate better on the subject matter. The course was a high value experience that provided more knowledge than was ever expected and has been a top recommendation for anyone who has the same interests as I. After reflection and reviewing my notes, here are some of the items/topics I valued the most.

The course was a classroom environment. I was reminded of the lab portion in some of my college courses, albeit a much more relaxed version. The objective was to learn. It was apparent people didn’t want to out themselves on what they didn’t know. That is human nature today. Mike and Dillon made it clear early on they respected those in attendance as individuals and they were there to teach. It was interactive. As components were explained, you had your own parts to view along with the TDP spec correct component being passed around. The few people who had inferior parts were provided quality parts to replace them with. The “why” behind the product being inferior was explained and linked back to priority #1. Variations and the history of components were also main topics. One of the departments was able to bring a Vietnam era Colt’s Manufacturing LLC rifle on day two. I hope every course attendee gets that type of extra moment. As a history buff, it successfully tickled my pickle.

The course was NOT a sales pitch. Credit was given to other brands for their quality/processes. Brands were not outed or named for perceived or actual flaws. Was the SOLGW logo present? Of course! Any successful company knows branding is vital to growth. However, the instruction/knowledge was not branded. The TDP spec was regularly referenced as the source of reason as were other respected subject matter experts. Parts were reviewed and inspected for quality and correctness, not for brand name. Any design changes from the original recipe, the VLTOR A5 system for example, were discussed in a “how does this improve the reliability of the rifle” forum.

Information wasn’t considered proprietary. It’s not uncommon to receive the response “we don’t disclose proprietary information” when asking a company for specifics of a part. Port sizes, measurements, tolerances, the reasons why. All were discussed, documented, and provided in the classroom. It was even communicated before the course that the attendees were encouraged to bring a flash drive so the presentation could be downloaded for future reference. In my opinion, the course could be adjusted to a 3-day course. This would provide more time overall as the end of both days felt rushed due to the facility closing. This is stated not as a complaint to the facility or that the instructors were trying to bail. Businesses have closing times, and the amount of discussion/instruction was large. That’s just how the timeframes collided. The third day would also provide test firing time which I think would add to the learner’s experience like the proverbial cherry on top. I do understand the scheduling conflict the third day would create for most people wanting to attend and the increase in cost. This opinion is a “in a perfect world” scenario.

By the end of the 2 days all my “why’s” were answered. The course provided a wealth of knowledge to advance my understanding of the AR-15 weapon system and it was delivered in an engaging classroom setting that facilitated open discussion. “Make a hole, fill a hole” and other phrases were learned so I could have a better discussion with people not as educated on the subject. It speaks loudly to a company’s culture when one of the owners leads the instruction. The course wasn’t centered around selling products but growing a movement through education within American society. After reflection, the mission was accomplished, and I built another rifle that I can say #thisthingfcks.